Modular construction has been touted as the cure for many of today's construction problems. Unfortunately, the skilled labor shortage, rising costs, and tightening schedules will not be solved by just buying a modular solution.

In the same way that buying fitness equipment doesn't improve our health on its own, neither will modular products. The proper use of the equipment is where the benefit comes from, and sometimes we need the help of a trainer or consultant to improve.

I have heard, "We tried modular electrical, and it doesn't work." Digging deeper, I often discover two reasons.

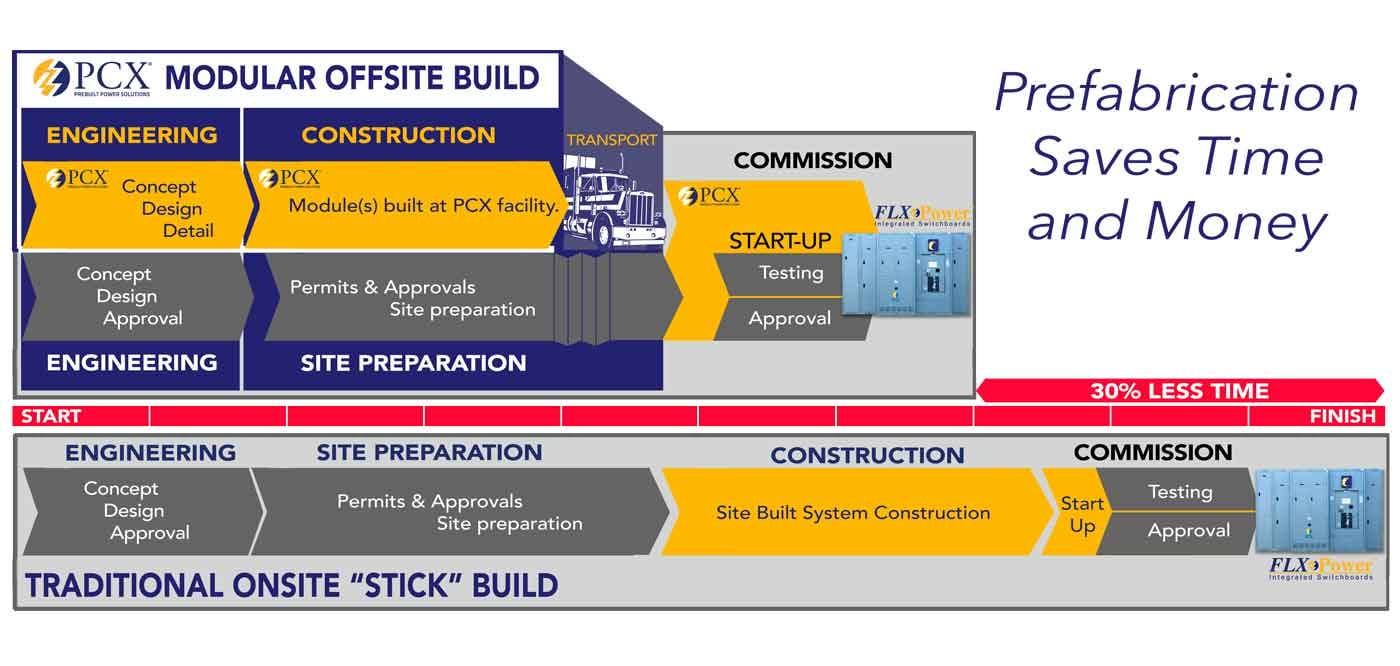

1.) The planned schedule didn't change. The equipment was installed at the same time loose panels would have been, though the modular solution could have been installed weeks ahead of time. Parallel processes have significant impact on schedules, but only if the early steps in the construction process change.

2.) The savings potential was not realized. This is because we are not comparing apples to apples. The equipment itself may not be cheaper, but how many labor hours did you remove from the site? Was your project priced with a modular solution as part of your bid package? Could more contractors bid your project if they didn't have to source all the gear? Would you still rent generators if permanent power was available onsite? These are just a few of the many opportunities for cost savings.

Integrated switchboards, modular powerwalls, and electrical distribution centers will not do anything for you on their own. It's not the product itself, but the process that it allows us to improve.

Find a solution provider that is willing to learn your construction process, and cares about improving your business.

_______________

Post by Rob Coyle, PCX Corporation, Commercial Construction

SaveSave

SaveSave

Comments